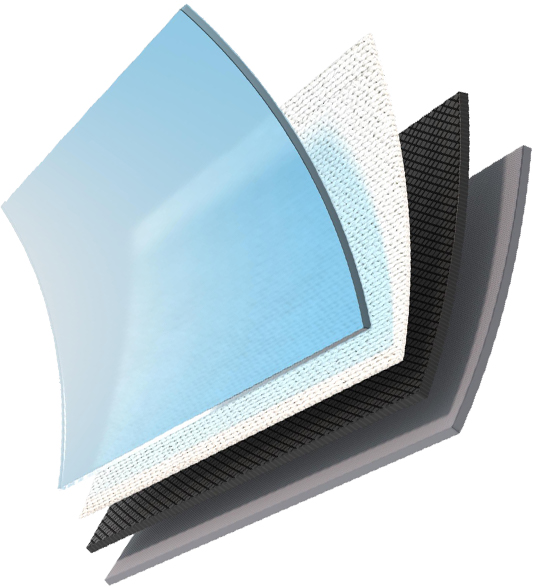

Modular Flavor Architecture

Deconstructing fragrance concentrates into four modules-Base,Modifier, Top Note, and Fixative-enabling meticulous calibration and development.

This modular approach fundamentally addresses the core challenges in e-liquid flavor creation: heavy reliance on subjective experience, ambiguous attribution of sensory effects, and difficulty in ensuring stability.

It transforms perfumery from an intangible "art of sensory intuition" into a structured "flavor engineering discipline" that is analyzable, designable, and predictable.

This modular approach fundamentally addresses the core challenges in e-liquid flavor creation: heavy reliance on subjective experience, ambiguous attribution of sensory effects, and difficulty in ensuring stability.

It transforms perfumery from an intangible "art of sensory intuition" into a structured "flavor engineering discipline" that is analyzable, designable, and predictable.